Molding Conductive Gasket

Molding conductive gasket is functioal silicone elastomer by adding conductive filler into silicone. Gasket has good conductive shielding effect anti-corrosion wide operation temperature range and long work life.

Description

Molding conductive gasket is functioal silicone elastomer by adding conductive filler into silicone. Gasket has good conductive, shielding effect, anti-corrosion, wide operation temperature range and long work life. Conductive filler can be Ni/C, Ag/G, Ag/Al and other customized filler.

Feature

▪ Low resistance and good shielding preformance

▪ Long work life

▪ Good mechanical performance

▪ Wide operation temperature range

Application

▪ Telecom

▪ Medical

▪ Military

Specification

| Performance | Test Standard | Filler | ||

| Al/G | Ag/Al | Ni/C | ||

| Hardness Shore A | ASTM D 2240 | 70±5 | 70±5 | 65±5 |

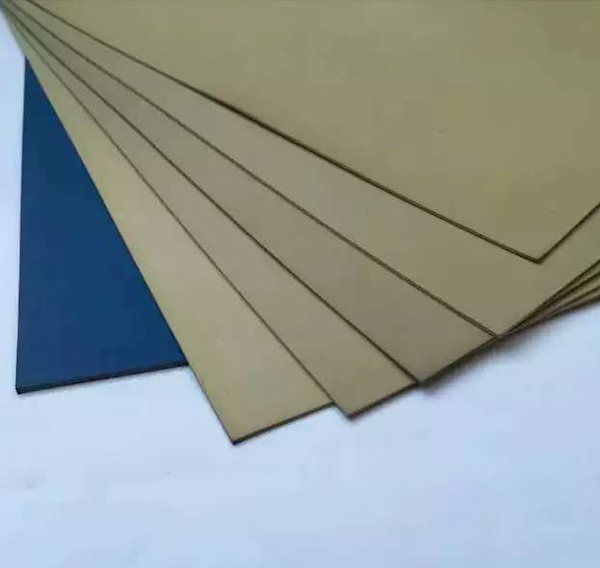

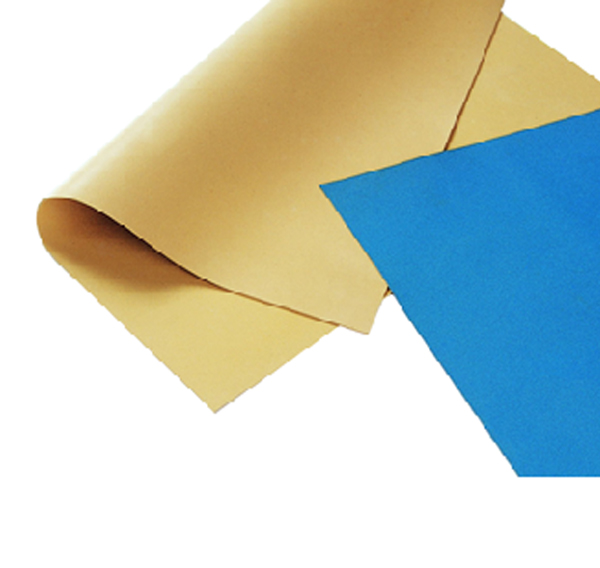

| color | / | yellow | Yellow/blue | black |

| Density,g/cm3±0.25 | ASTM D792 | 2.0 | 2.1 | 2.0 |

| Tensile Strength,MPa | ASTM D412 | 2.0 | 2.5 | 2.0 |

| Elongation,% | ASTM D412 | 200 | 200 | 250 |

| Tear Resistance,kN/m | ASTM D624 | 7 | 8 | 9 |

| Volume Resistance,Ω•cm | MIL-DTL-83528 C | 0.01 | 0.008 | 0.1 |

| Shielding performance,dB | ||||

| 200kHz(H-Field) | MIL-DTL-83528 C | 50 | 60 | 50 |

| 100MHz(E-Field) | MIL-DTL-83528 C | 100 | 115 | 100 |

| 500MHz(E-Field) | MIL-DTL-83528 C | 100 | 110 | 100 |

| 1GHz(Plane Wave) | MIL-DTL-83528 C | 90 | 105 | 90 |

| 2GHz(Plane Wave) | MIL-DTL-83528 C | 90 | 105 | 90 |

| 10GHz(Plane Wave) | MIL-DTL-83528 C | 80 | 100 | 90 |

| Operation Temp,℃ | ASTM D1329 | -55~160 | -55~160 | -55~160 |

| Compression Set,% (100℃*70h*30%),Max | ASTM D395 | 30 | 30 | 17 |

| Flaming Rate | UL 94 | V1 | V1 | V1 |

| Process | / | Molding | Molding | Molding |

188-2226-7107

TIANJIN BROTHERS TECHNOLOGY CO., LTD.

Tel: 18822267107

Email:gavin.ma@brothers-tech.com

PRODUCTS

PRODUCTS